Asco Manufacturing

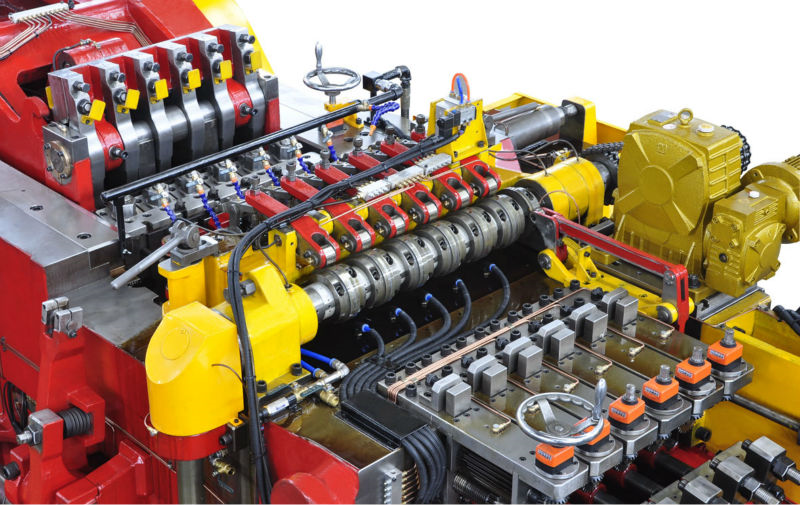

Asco Fixings has been manufacturing fasteners since its inception in West Bromwich in 1998. However, in order to take advantage of lower cost of production, we moved our factory to the north of India and added to our capability and capacity in our 20,000 sqft site. In house services also include CAD/CAM and testing facilities.

Our objective is to provide our customers with a broad range and flexibility of products offering. We are now able to manufacture the following range of quality metal components:

FASTENERS

Thread forms standards: Metric, BS, DIN, ANSI, ISO, JIS, IS or according to customer drawings

Sizes: M3 to M16, up to 150mm length

Head types: Hexagon Head, Square Head, Cup Square, Cup Round, CSK Square, CSK Round, and more

Materials: Mild Steel, Alloy Steel, Boron Steel, Stainless Steel, Brass, Aluminum, Copper

Metric Grades - Mild Steel Grade 4.6 to High Tensile Grade 14.9

Surface finishes: Zinc Plated, Galvanised, Dacromet, Geomet, eCoating

PRESS PARTS / SHEET METAL

Small press parts of few centimetres to two meters long

Press machine capacity of 75 tonnes

Sheet metal thickness of up to 10mm

Material: Sheet - CREDD, CRCD, CRC, HRC; Tube - CEW / ERW

Examples - body parts for motorcycles, brackets, prop stands, spring housing, chain tensioners etc.

FABRICATION AND ASSEMBLY

Skilled welders and fabricators manufacture components to customer requirements

Processess include Bending, Grinding, Cutting, Machining, Punching, Welding

Asco Infrastructure

The following are the list of machinery in our factory:

5 Bolt Formers

7 Bolt Headers

7 Thread Rollers

Trimmer

3 Head Slotters

6 Lathes

8 Power Presses

Mig welding and Automatic Mig Rotary Welding

Site and contents © 2020-21 Asco Fixings Ltd.